Intelligent Forecasting of Mechanical Properties in 3D Printing using AI

Project Overview

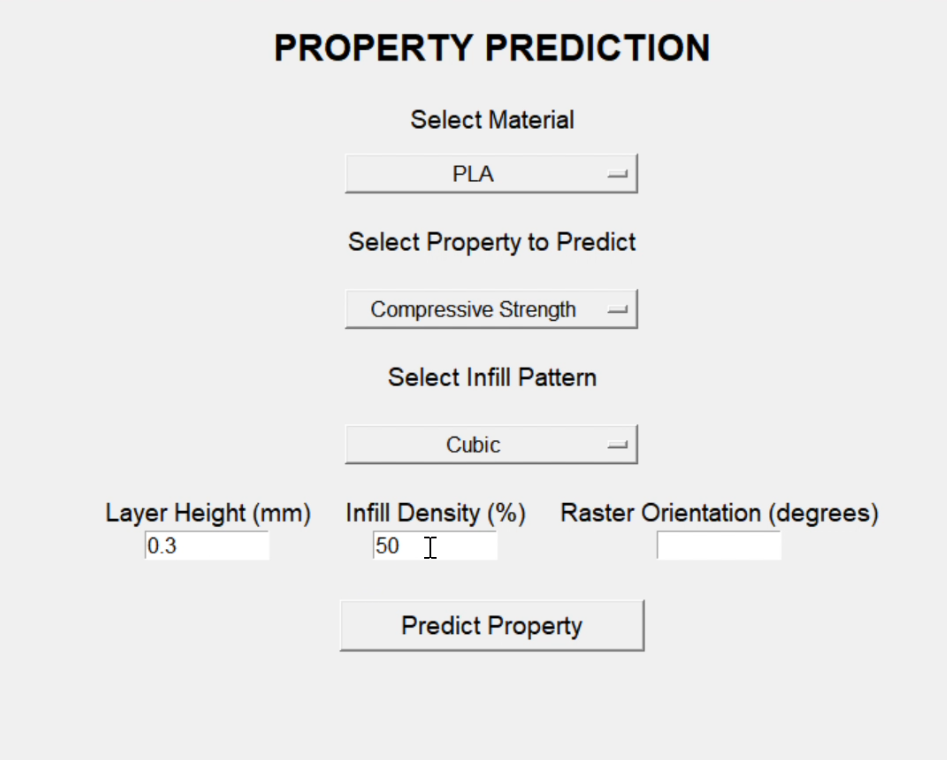

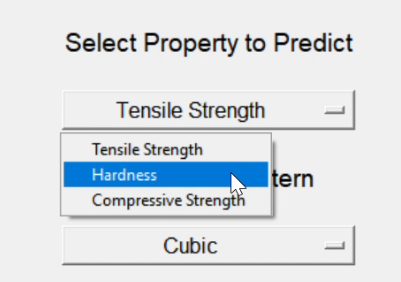

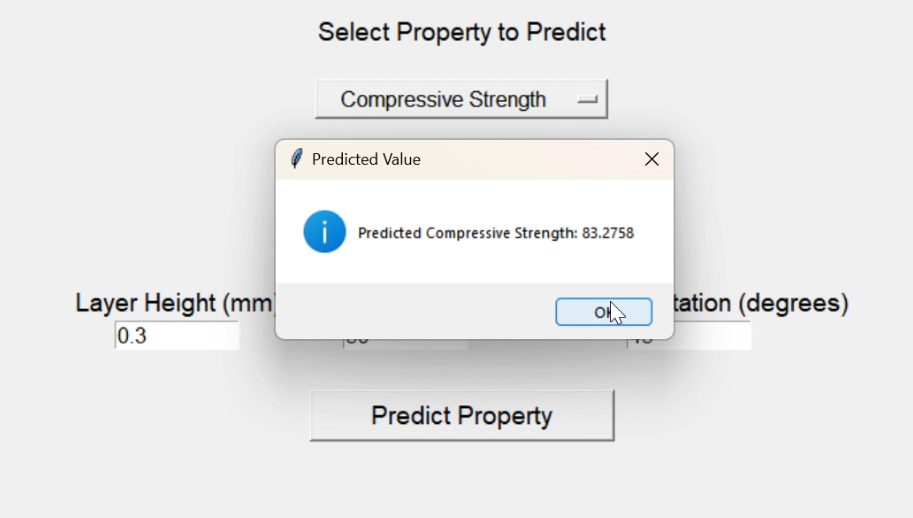

This innovative project focuses on leveraging artificial intelligence to predict the mechanical properties of 3D printed parts based on input parameters. By analyzing factors such as material type, layer height, and infill pattern, our ML models can accurately forecast tensile strength, hardness, and compressive strength without the need for extensive physical testing.

The system addresses a significant challenge in additive manufacturing: the time-consuming and costly trial-and-error approach traditionally required to achieve desired mechanical properties. Our solution dramatically reduces development cycles while improving material efficiency and overall productivity.

Project Details

The Intelligent Forecasting system for 3D printing delivers several key innovations and benefits:

- Advanced Property Prediction: Developed ML models using Random Forest and XGBoost algorithms to accurately predict mechanical properties like tensile strength, hardness, and compressive strength based on various input parameters.

- Real-time Optimization System: Designed a system that automatically optimizes material usage and print settings to achieve desired mechanical properties while maximizing manufacturing efficiency.

- Intelligent Feedback Loops: Integrated continuous learning mechanisms that incorporate new test data to enhance model accuracy over time, reducing reliance on traditional trial-and-error methods.

- Patent-Pending Technology: Applied for patent protection due to the system's innovative approach and significant impact on improving additive manufacturing processes.

The project has demonstrated remarkable accuracy in predicting mechanical properties, with validation tests showing over 90% correlation between predicted and actual measurements across various materials and print settings.

Technical Implementation

The forecasting system utilizes a sophisticated data pipeline that processes and analyzes thousands of test samples. We employed ensemble methods combining Random Forest and XGBoost algorithms to handle the complex, non-linear relationships between printing parameters and resultant mechanical properties.

Feature engineering played a crucial role in identifying the most significant parameters affecting mechanical properties. Our analysis revealed that certain combinations of layer height, infill pattern, and printing temperature had disproportionate effects on final part strength, leading to the development of specialized optimization algorithms.

Project Gallery